Capabilities Statement

Zanesville Steel specializes in the engineering, fabrication and distribution of steel racking systems. While our core competencies are designing and manufacturing racking systems, our capabilities and experience include detailing and fabricating structural and miscellaneous metal products for commercial, industrial, retail and a vast array of residential markets.

About Us

Over 200 years of combined experience in:

- Structural Welding

- Miscellaneous/Ornamental Fabrication

- Multi-Process Welding

- Operating Fabrication

- Equipment/Technology

- Engineering

- Painting

- Industrial Miscellaneous Metals Fabrication

- Commercial Construction Fabrication

Zanesville Steel has 20 years experience working for and with Government Agencies both domestic and abroad in various construction capacities.

Key Differentiators

One Stop Shop from Engineering to Finished Product

HUB Zone Small Business

Customizable fabrication to meet customers’ specific needs

Large volume raw material buying power

Rapid turnaround

Highest Standards of Quality

OSHA 30hr Trained

Made in the U.S.A.

CAPABILITIES, EQUIPMENT, SERVICES AND SPECIALTIES

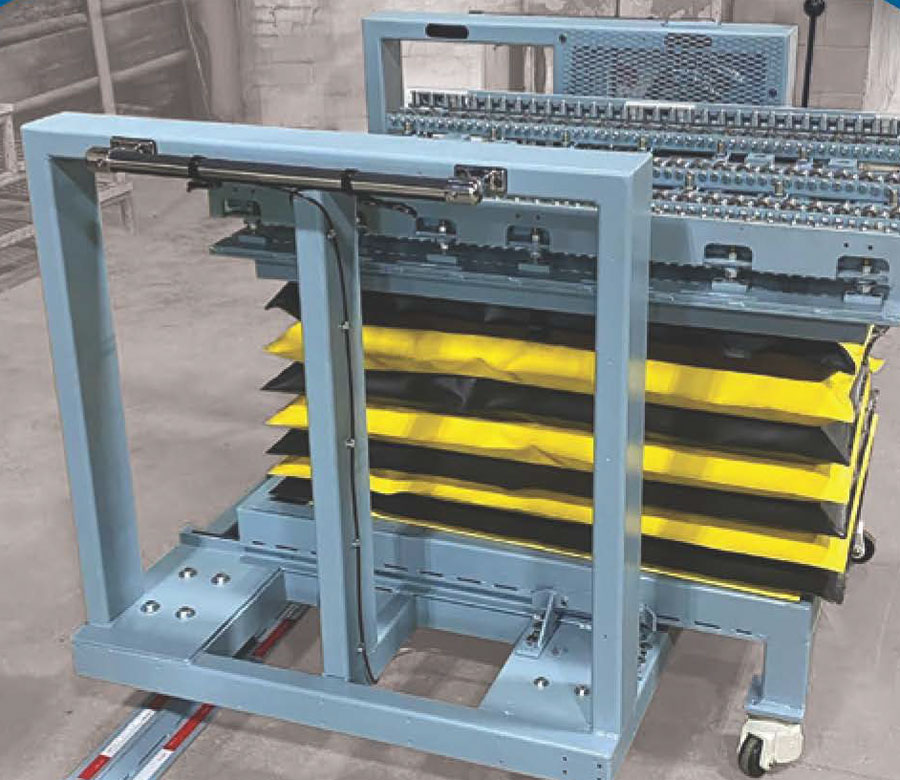

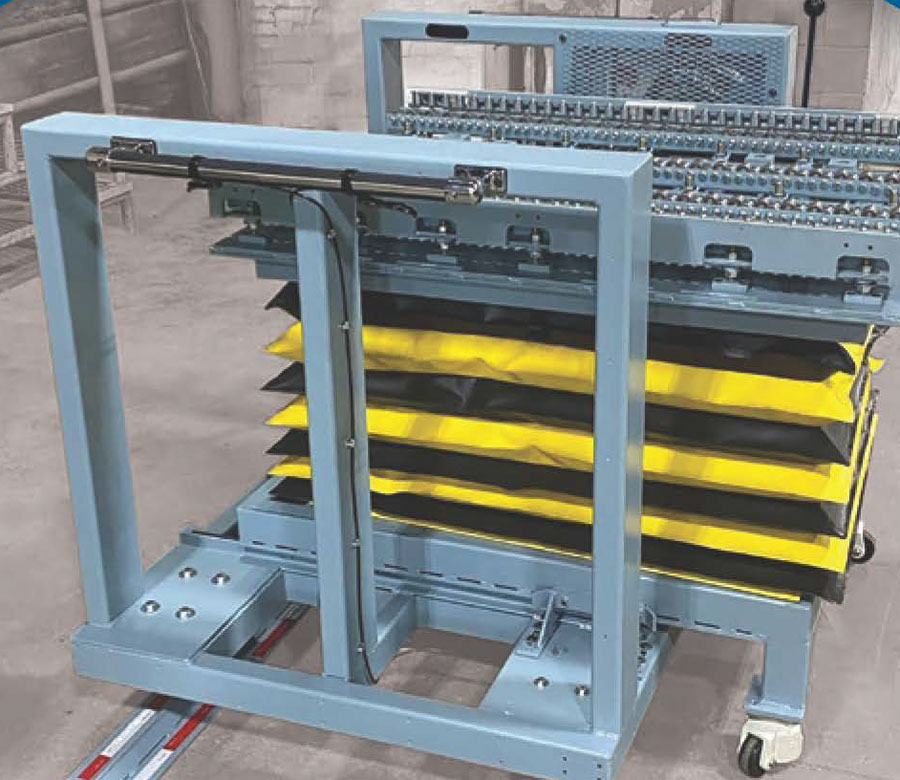

Stackable Steel Racking Systems

Miscellaneous Metals

- Stairs

- Hand Railings

- Platforms

- Light Structural

- Gates

- Ladders

- Supports

- Architectural & Ornamental Metal Work

Large Capacity Production Saw

Mill Direct Steel Buying Power

Certified Welders

Welding Multiple Processes

Fabrication Equipment

Reverse Engineering Capabilities

Overhead Crane

Electrostatic Painting

CNC Plasma Tube and Pipe Cutting

- Can cut Round, Square, Rectangle steel tube and pipe

- Steel, stainless steel, galvanized steel, aluminum, and black pipe

- Accepts most commonly used CAD programs (such as Solidworks, Inventor, AutoCAD, PRO Engineer, Tekla, SDS2, etc.)

- 1/32” to 5/8” thick

- 24’ long

- 400lb capacity

- 1” to 6” round

- 1” to 4” square and rectangle

- Plasma Cutting

- Marking

- Engraving

- Hole cuts

- End Cuts

- Slots

- Miters